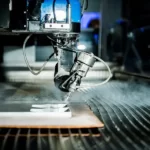

Waterjet technology is a cold cutting process which cuts by using supersonic water, or water and abrasive, to erode material. Because of this, waterjets are unlimited in what they can cut.

1. Generate Pressure

An ultrahigh-pressure pump generates a stream of water with pressure rated up to 94,000 psi (6,480 bar). To put it into perspective, a fire hose contains a pressure of 390 to 1,200 psi (20 to 84 bar).

2. Convert Pressure into Velocity

This pressure is converted into velocity via a tiny jewel orifice, creating a stream as small as a human hair which can cut soft materials.

3. Introduce Garnet

To increase cutting power by 1,000x, garnet is pulled into the supersonic waterjet stream. Water and garnet exit the cutting head at nearly four times the speed of sound, capable of cutting steel over one foot thick.

Pure & Abrasive Waterjet

There are two types of waterjet: pure and abrasive. Combined, these two technologies can cut virtually any material, any shape, at any thickness.

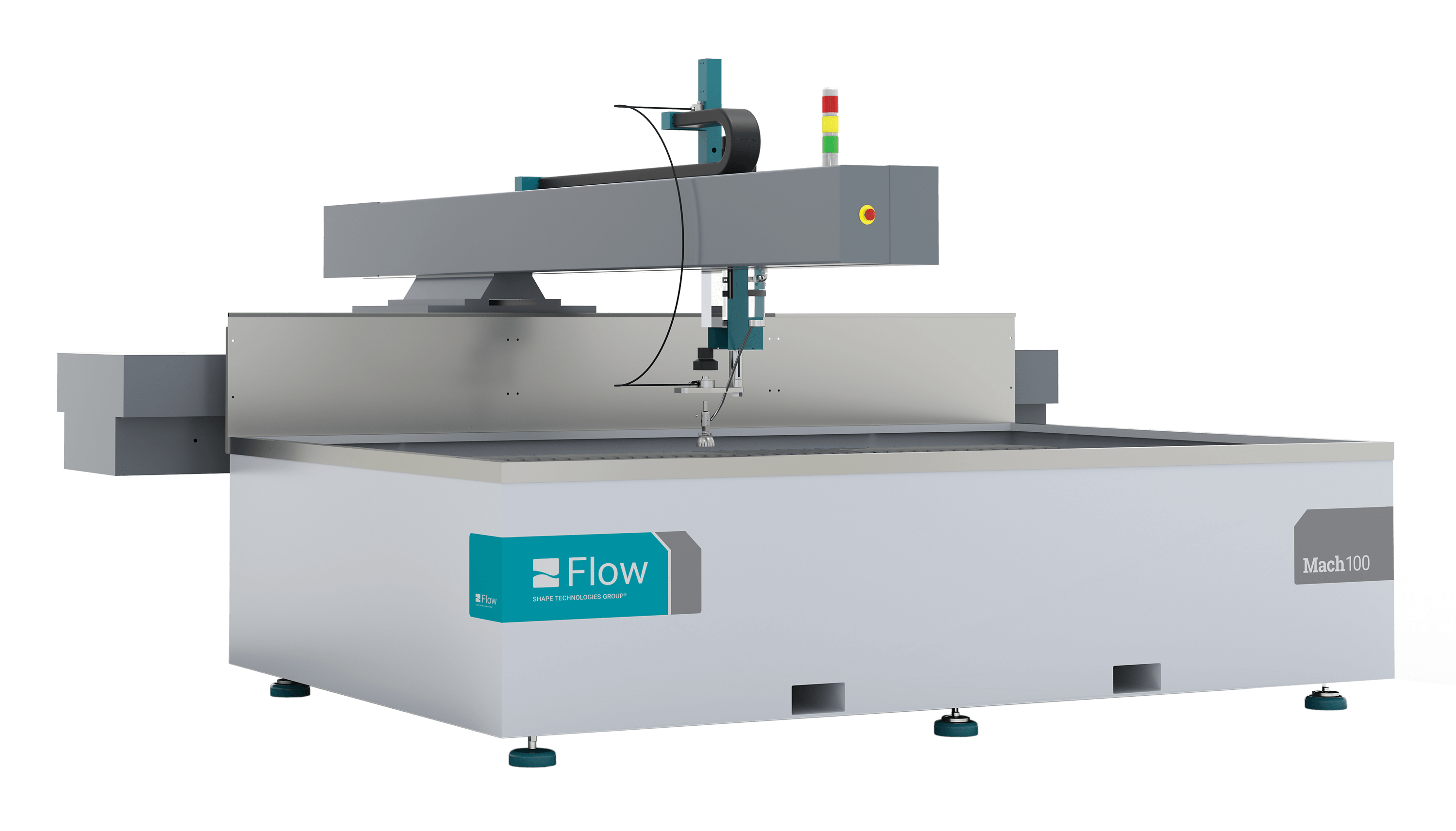

Components of Waterjet

A waterjet is more than just pressurized water and sand. The shapecutting system is comprised of:

1 |

The Ultrahigh-Pressure System

includes the pump, cutting head, and plumbing |

2 |

The Machine

includes the X, Y, Z axes, cutting head wrist axes, and material support catcher |

3 |

The Control System

includes the programming software, operator interface, drive motors, and position and velocity feedback system |