The 5 Most Common Waterjet Questions

For those doubting water as an effective cutting tool: think again.

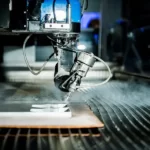

Waterjet technology is known for its power and favored for its ability to split just about any material in half. We’ve gone over this before – the combination of 60,000 Pounds per Square Inch (PSI) of pressure and abrasive garnet turns a seemingly benign hydraulic stream into a serious power tool.

Waterjet can cut through stone, metal, and other formidable materials. But what else? As the final article in our 5-part series on the 5 Most Common Waterjet Questions, we address the question everyone has on their minds, what are some of the coolest things you’ve seen waterjet cut? Buckle up, we’re about to share some of our favorites.

24” Thick Steel

If there’s any material that is seemingly impervious, it’s steel. Steel is made of iron and carbon and one of the most-used components in industrial fabrication. However, it’s no match for waterjet.

Waterjet’s tempered, consistent stream has the ability to easily cut through 24 inches – yes, two feet – worth of steel. Don’t believe us? Check out the image below of a 24-inch thick, contoured piece of steel cut in the dry docks. Amazing!

Food

A waterjet isn’t a staple in the kitchen. But that doesn’t mean it’s an impractical culinary tool.

In fact, waterjet cutting is approved by the United States Department of Agriculture and is more sanitary than using a knife. No blade means no bacterial transfer from blade to food. Meats, poultry, fish, produce, pastries, and frozen foods can all be cut with a waterjet.

In industrial settings, meat, vegetables and even candy bars – yes, candy bars – are cut using waterjet machines. Waterjet offers consistent cut sizes and efficiency, making the machine an extremely helpful tool in the food industry.

Gourds represent another, albeit interesting, use case: Watch a waterjet

Extremely Small Materials (Microcutting)

We often think about all of the large, impressive things waterjet can cut. But its dexterity dealing with small pieces of material is just as impressive. Microcutting refers to waterjet’s ability to cut tiny pieces of materials – ranging anywhere from 0.001″ to 0.125.”

Microcutting applications include watchmaking or creating circuit boards and the production of small electronics. And just because you’re cutting at microlevels doesn’t mean you have to sacrifice precision or repeatability. In fact, our waterjet solution is specifically designed as a highly accurate, small format waterjet machining center.

Art

Waterjet projects often conjure up images of industrial applications: the creation of automotive parts, turbine blades, fiberglass components. But the technology can also be used to create beautiful pieces of art.

Waterjet’s precise cutting ability makes it a perfect tool for producing intricate inlays with ceramics, metal, and other materials.